The screw packaging machine is an automatic packaging process realized by automatic feeding, sealing, arrangement and counting through the vibrating tray. The screw packaging machine can also be equipped with a pure automatic feeding mode to realize the automatic packaging process. Of course, all the customization details are customized according to the products you provide and the actual production needs of your company. Yes, it is a tailor-made device, your details are in place, our device details can be better! This equipment is suitable for automatic counting packaging of five workpieces in various industries, instead of traditional manual operations, it is a gospel equipment for production efficiency.

Here are the machine’s functions and features, please kindly check the follow points.

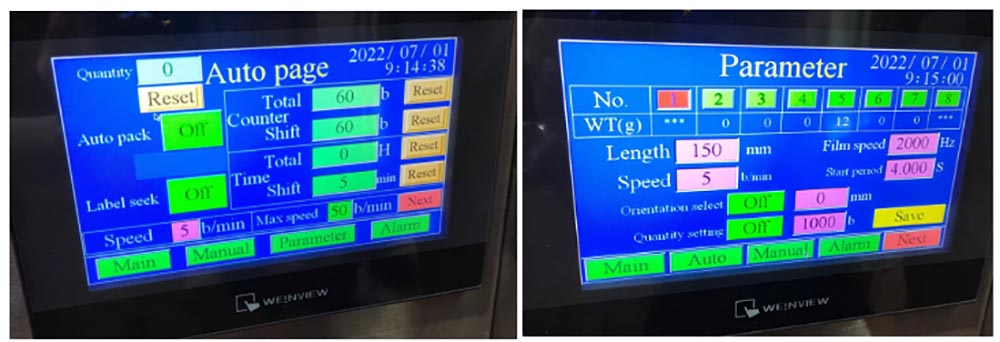

1.Our machine is controlled by the touch screens from TaiWan’s Weinview. And the controlling system is PLC , so it is very easy for the workers to operate. By the way, you could adjust the bag different bag length on the touch screen.

2.The packaging industry realizes the printing of QR code, barcode, batch number and other information on the packaging film of the screw packaging machine. Labels are also available.

3.The packaging industry adopts Shanghai vibrating disc with Taiwan technology. The surface of the vibrating disc is sprayed with DuPont glue, which will not cause any damage to the material. It has low noise and large bearing capacity. The weight of a single disc varies from 40 to 160 kg. The material is discharged more smoothly. The counting system is selected according to the specific material of the customer.

4.Each set of vibrating plate is equipped with material full stop, material shortage alarm or stop device to ensure the accuracy of each bag. The equipment has a self-diagnosis function, and can automatically alarm or stop when a fault occurs (the alarm or shutdown can be selected by the user). It is equipped with multiple emergency stop buttons, which is convenient for operation.

5.The equipment can realize automatic arrangement, automatic counting, filling, sealing, packaging, conveying, sorting and packing of materials. The number of product packaging can be adjusted at will, the number of packaging bags can be controlled by itself, the number of packaging can be automatically displayed, and the workload of the machine can be easily counted.

6.The screw packaging machine has automatic detection of no material and lack of material. When there is no material or no material, the equipment will automatically stop and alarm. Each feeder in the equipment can be turned on or off at will to facilitate production needs. The maximum number of stations of the screw packaging machine is: 64 stations

7.The industry adopts two sets of polyethylene chain tracks installed in the chain bucket, and the chain bucket is more stable, safe and low in noise during the forward process. The stainless steel body has a neat and clean appearance. The packaging industry adopts a lowering height conveying system, which completely breaks the traditional linear chain bucket conveying height is too high, which is convenient for feeding and maintenance.

If you also want to use this machine to count and pack the fasteners and screws, feel free to contact us . Our sale managers and engineers will be help to support you online. We will recommend you suitable packing solution.