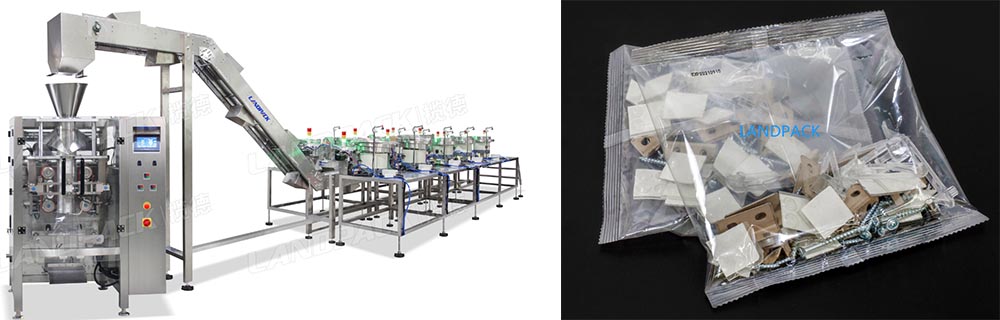

Hardware screw packaging machine can be said to be a kind of equipment widely used by modern processing enterprises when packaging granular products, especially in hardware, furniture, lighting, electrical appliances, household accessories, food and medicine, plastics and other industries. If it encounters the peak season of food, hardware and plastic packaging, the company has to operate in large quantities for a long time, which will undoubtedly aggravate the wear and tear of the hardware screw packaging machine. At this time, the operator is also required to clean the key parts of the metal screw packaging machine in time, so as to effectively prevent the aging of the metal screw packaging machine, and at the same time, it can reduce the failure rate of the equipment to a certain extent.

A good product should maximize its unique functions. Fair use is a condition that must be observed. Regular maintenance is more important. As the saying goes, if a thousand-mile ant nest is proposed, it is impossible to ignore small problems, so as to avoid affecting production and manufacturing, and to ensure that products are not damaged under large-scale production conditions. For the hardware screw packaging machine, there are many aspects that need to be paid attention to. In order to achieve reasonable use, efficient and stable production, its protection is also essential.

Good mechanical equipment is not afraid of long-term use, but is afraid of long-term use without paying attention to cleaning and maintenance, especially for metal screw packaging machines. Long-term use will not cause any damage to the body, but if the cleaning and maintenance work is ignored, then the hardware screw packaging machine will soon have problems. As the application of the hardware screw packaging machine becomes more and more extensive, its role in the production enterprise becomes more and more important, so more and more users will pay more attention to the maintenance of the equipment.

The basic cleaning work of the hardware screw packaging machine is as follows:

1. After the machine is stopped, the metering parts, such as sugar, salt, powder, liquid, etc., should be cleaned in time to ensure that the feeding tray and turntable are cleaned every day to prevent corrosion.

2. The materials scattered on the tray should be cleaned up in time to keep the parts clean.

3. The photoelectric tracking head or electric eye should also be cleaned regularly to ensure that the cursor tracking error is small.

4. For the heat-sealed body, it should be cleaned frequently to ensure a clear texture of the seal.

5.Regularly clean the dust in the electric control box to prevent failures such as poor contact of the hardware screw packaging machine.